|

Have any Questions? +86 20 8608 6778 |

KT-50 Automatic Granular Packing Machine

Mechanical characteristics and product characteristics:

1. The equipment is easy to operate and easy to maintain.

2. The whole bracket is made of all stainless steel, non-outsourced stainless steel;

3. The equipment is compatible, and different specifications can be realized by changing the mold;

4. Good fluidity materials, no dust, three-side seal design, electric high-speed models

5. Auxiliary equipment: loading machine + ribbon coding machine

Mechanical characteristics and product characteristics:

1. The equipment is easy to operate and easy to maintain.

2. The whole bracket is made of all stainless steel, non-outsourced stainless steel;

3. The equipment is compatible, and different specifications can be realized by changing the mold;

4. Good fluidity materials, no dust, three-side seal design, electric high-speed models

5. Auxiliary equipment: loading machine + ribbon coding machine

Features:

1. Using a rotary cutter to cut, by replacing the blade, the flat mouth and the serrated mouth effect can be realized, and the bag length cutting position is convenient to adjust;

2. Full pneumatic control including metering and bag making, simple operation, less wear parts in the later period, reducing parts replacement;

3. Material: The material contact part is made of SUS304 stainless steel, which meets the requirements of GMP production.

4. The heat-generating parts and moving parts are hidden in the protective cover and are safe to operate.

5. The equipment is equipped with casters for easy handling and movement.

Technical Specifications:

|

Filling range |

1-50g |

|

Sachet size |

W:30-100mm L:30-150mm |

|

Max. film width |

220mm |

|

Sachet type |

side sealing bag type |

|

Filling method |

Volumetric cups |

|

Control |

EASY PACK control |

|

Capacity |

30-60ppm |

|

Power |

220V50-60HZ/1.0KW |

|

Air |

0.3m³/min 0.6-0.8Mpa |

|

Materials |

Contacting parts SUS304 |

|

Dimension(L*W*H) |

670*850*1655mm |

|

Weight |

200KG |

Features:

1. Using a rotary cutter to cut, by replacing the blade, the flat mouth and the serrated mouth effect can be realized, and the bag length cutting position is convenient to adjust;

2. Full pneumatic control including metering and bag making, simple operation, less wear parts in the later period, reducing parts replacement;

3. Material: The material contact part is made of SUS304 stainless steel, which meets the requirements of GMP production.

4. The heat-generating parts and moving parts are hidden in the protective cover and are safe to operate.

5. The equipment is equipped with casters for easy handling and movement.

Technical Specifications:

|

Filling range |

1-50g |

|

Sachet size |

W:30-100mm L:30-150mm |

|

Max. film width |

220mm |

|

Sachet type |

side sealing bag type |

|

Filling method |

Volumetric cups |

|

Control |

EASY PACK control |

|

Capacity |

30-60ppm |

|

Power |

220V50-60HZ/1.0KW |

|

Air |

0.3m³/min 0.6-0.8Mpa |

|

Materials |

Contacting parts SUS304 |

|

Dimension(L*W*H) |

670*850*1655mm |

|

Weight |

200KG |

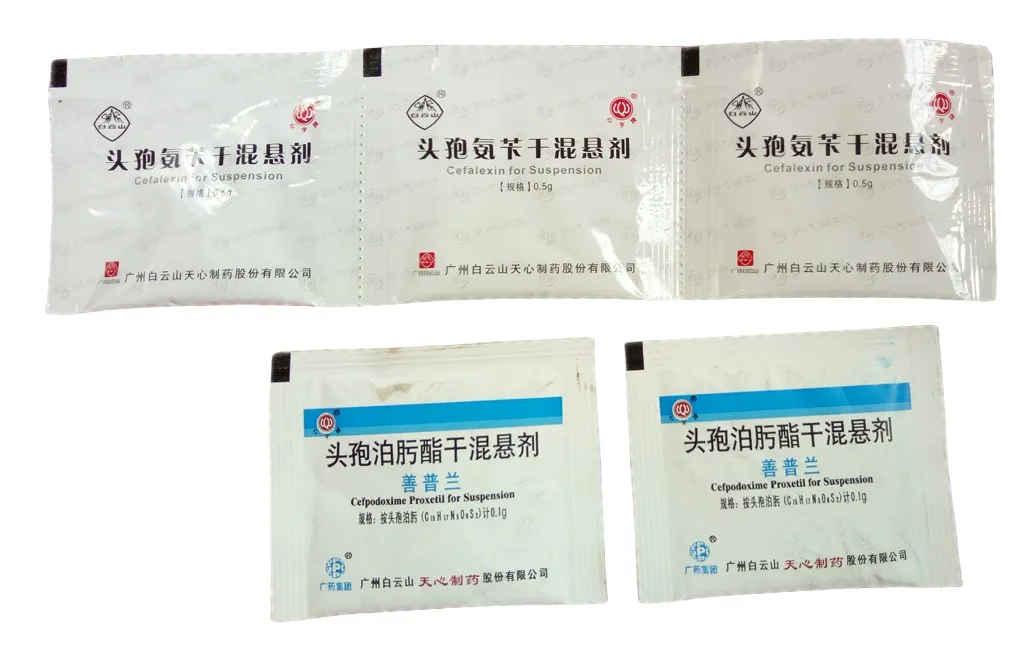

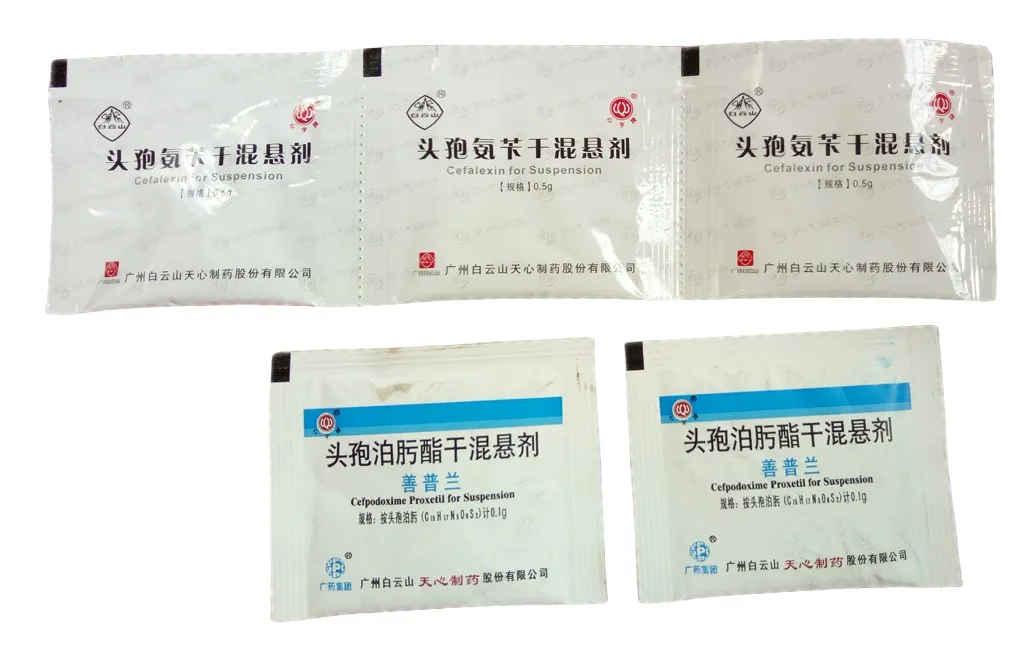

Bag sample picture as below:

Bag sample picture as below: