|

Have any Questions? +86 20 8608 6778 |

XY-A Fixed Type Vacuum Homogenizing Emulsifier

Feature

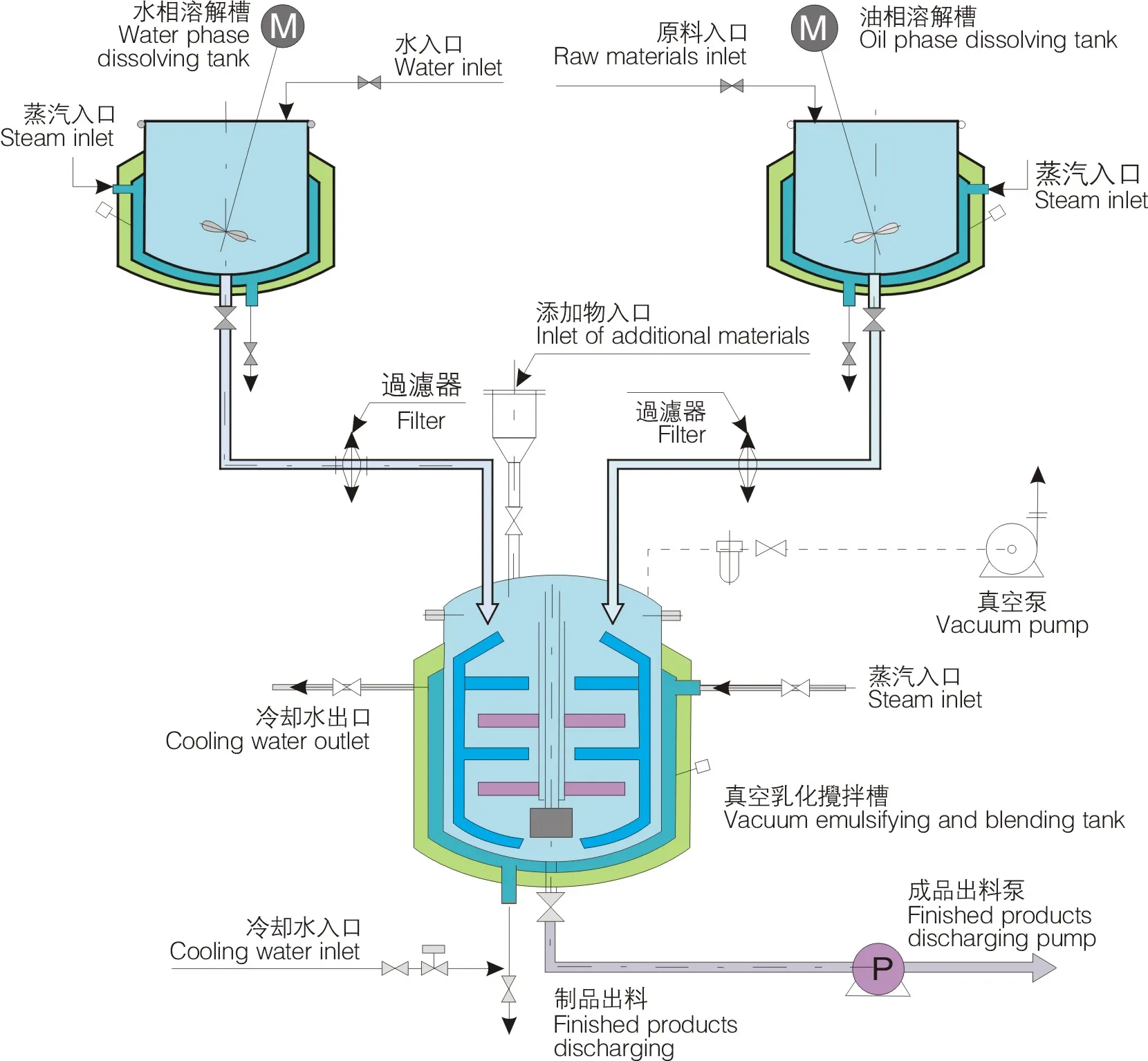

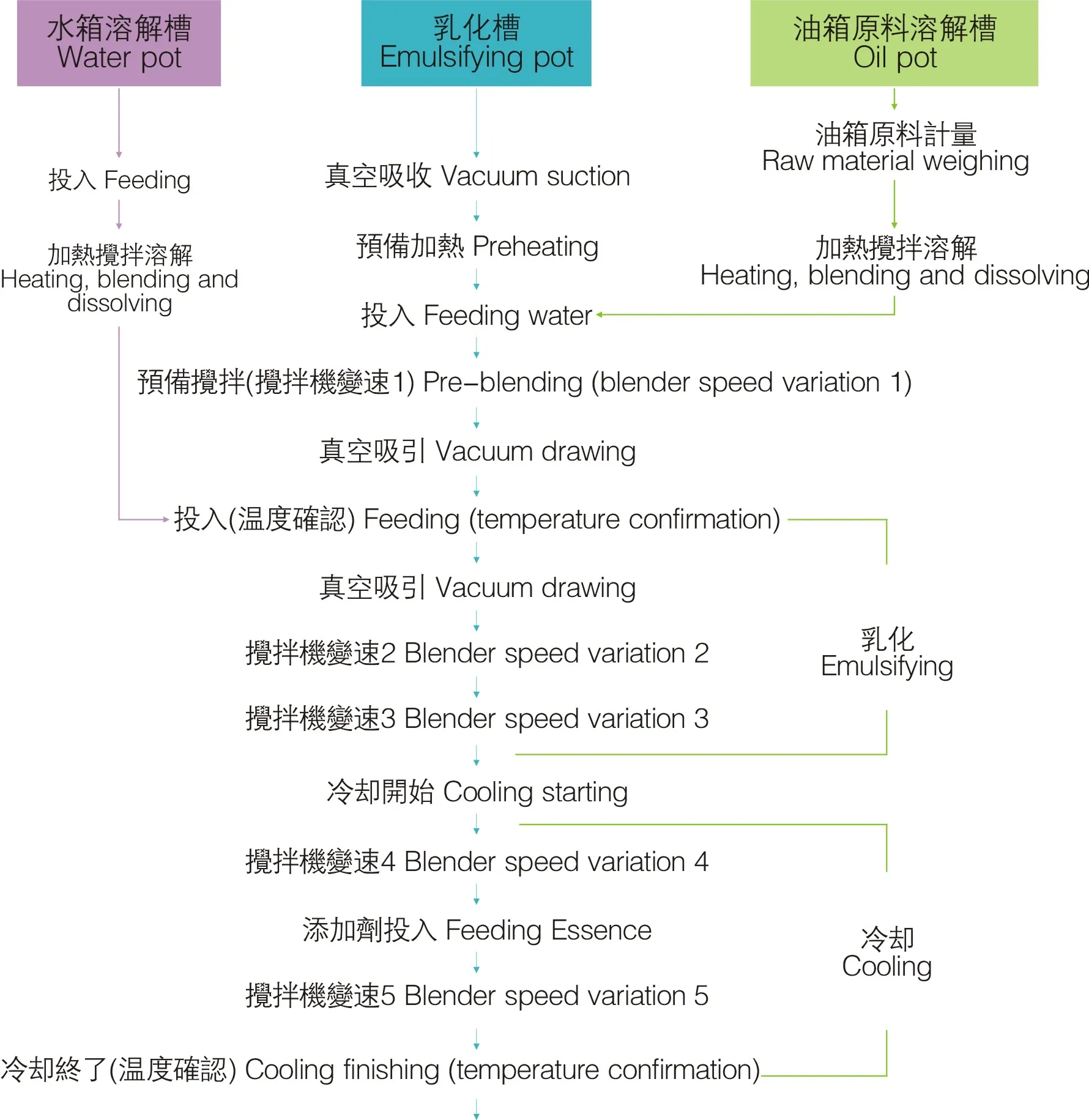

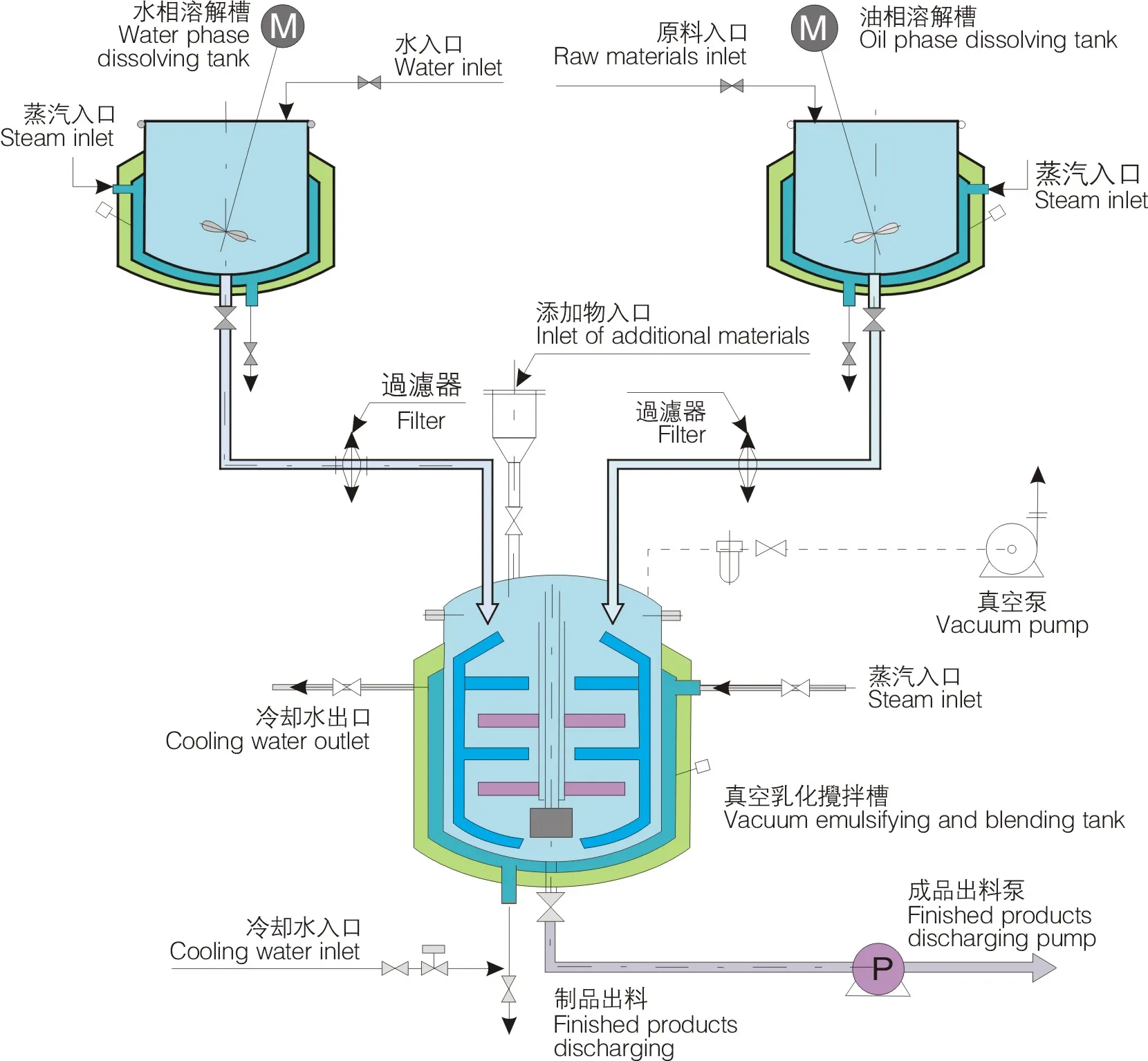

Integrating vacuum defoaming, blending, homogenizing, heating and electric control etc. functions, the equipment is an ideal device for producing high and middle level creams and honeys etc. The equipment is composed of vacuum homogenizing and emulsifying boiler, oil phase boiler, water phase boiler, operation platform, vacuum system and material pressing system etc.

Feature

Integrating vacuum defoaming, blending, homogenizing, heating and electric control etc. functions, the equipment is an ideal device for producing high and middle level creams and honeys etc. The equipment is composed of vacuum homogenizing and emulsifying boiler, oil phase boiler, water phase boiler, operation platform, vacuum system and material pressing system etc.

Capability & Characteristic

Stepless speed adjustment is adopted during the blending so that the speed of blending line can be randomly adjusted within the range of 0-63 RPM to meet different technological requirements.

The advanced homogenizer adopts technology from USA ROSS Company, featured by unique structure and prominent efficiency.

The parts that contact the materials are all made of imported stainless steel. The interior surface of the vessel is subjected to mirror polishing 300EMSH (sanitary level), which is in accordance with sanitary requirements.

The whole process including vacuum material suction and vacuum defoaming can be completed under the vacuum status without cellular contamination, and thus, prolonging shelf life of products.

Beautiful and decent appearance, which adopts special polishing technology so that it is shining like a mirror, displaying luxurious character.

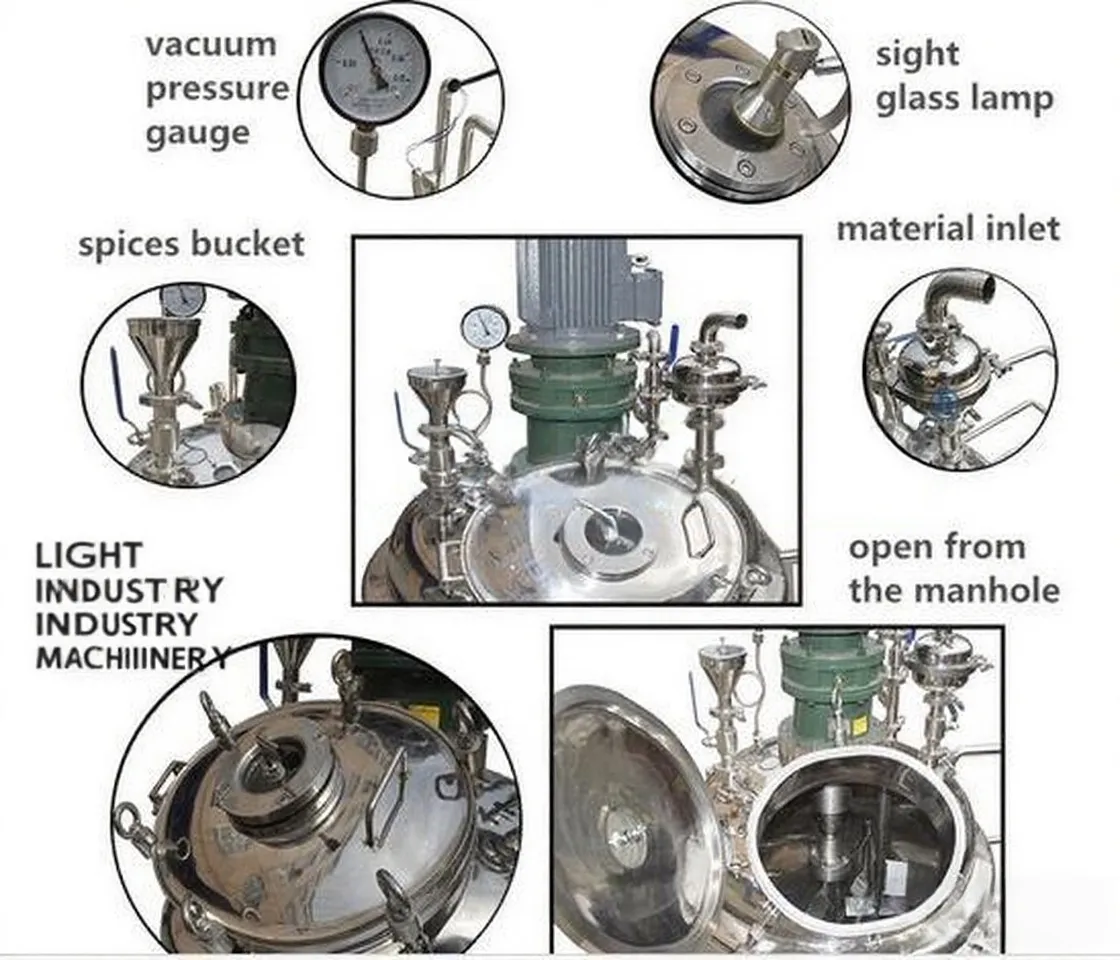

Machine details.

High shearing homogenizer

Technical parameter:

|

Model |

Volume (L) |

Homogenizer motor |

Stirring motor |

Total power |

Weight(KG) |

|||

|

KW |

RPM |

KW |

RPM |

Electric heating |

Steam heating |

|||

|

XY-A-100 |

100 |

3 |

0-3000 |

1.5 |

0-60 |

23 |

9 |

800 |

|

XY-A-150 |

150 |

3 |

0-3000 |

1.5 |

0-60 |

25 |

9 |

900 |

|

XY-A-200 |

200 |

4 |

0-3000 |

2.2 |

0-60 |

38 |

12 |

1000 |

|

XY-A-300 |

300 |

5.5 |

0-3000 |

3 |

0-60 |

46 |

16 |

1200 |

|

XY-A-500 |

500 |

7.5 |

0-3000 |

5.5 |

0-60 |

50 |

18 |

1300 |

|

XY-A-1000 |

1000 |

11 |

0-3000 |

7.5 |

0-60 |

80 |

30 |

1800 |

|

XY-A-2000 |

2000 |

15 |

0-3000 |

7.5 |

0-60 |

100 |

38.5 |

2000 |

|

XY-A-3000 |

3000 |

18.5 |

0-3000 |

11 |

0-60 |

120 |

49 |

2500 |

|

XY-A-5000 |

5000 |

22 |

0-3000 |

15 |

0-60 |

140 |

56.5 |

3000 |

Capability & Characteristic

Stepless speed adjustment is adopted during the blending so that the speed of blending line can be randomly adjusted within the range of 0-63 RPM to meet different technological requirements.

The advanced homogenizer adopts technology from USA ROSS Company, featured by unique structure and prominent efficiency.

The parts that contact the materials are all made of imported stainless steel. The interior surface of the vessel is subjected to mirror polishing 300EMSH (sanitary level), which is in accordance with sanitary requirements.

The whole process including vacuum material suction and vacuum defoaming can be completed under the vacuum status without cellular contamination, and thus, prolonging shelf life of products.

Beautiful and decent appearance, which adopts special polishing technology so that it is shining like a mirror, displaying luxurious character.

Machine details.

High shearing homogenizer

Technical parameter:

|

Model |

Volume (L) |

Homogenizer motor |

Stirring motor |

Total power |

Weight(KG) |

|||

|

KW |

RPM |

KW |

RPM |

Electric heating |

Steam heating |

|||

|

XY-A-100 |

100 |

3 |

0-3000 |

1.5 |

0-60 |

23 |

9 |

800 |

|

XY-A-150 |

150 |

3 |

0-3000 |

1.5 |

0-60 |

25 |

9 |

900 |

|

XY-A-200 |

200 |

4 |

0-3000 |

2.2 |

0-60 |

38 |

12 |

1000 |

|

XY-A-300 |

300 |

5.5 |

0-3000 |

3 |

0-60 |

46 |

16 |

1200 |

|

XY-A-500 |

500 |

7.5 |

0-3000 |

5.5 |

0-60 |

50 |

18 |

1300 |

|

XY-A-1000 |

1000 |

11 |

0-3000 |

7.5 |

0-60 |

80 |

30 |

1800 |

|

XY-A-2000 |

2000 |

15 |

0-3000 |

7.5 |

0-60 |

100 |

38.5 |

2000 |

|

XY-A-3000 |

3000 |

18.5 |

0-3000 |

11 |

0-60 |

120 |

49 |

2500 |

|

XY-A-5000 |

5000 |

22 |

0-3000 |

15 |

0-60 |

140 |

56.5 |

3000 |

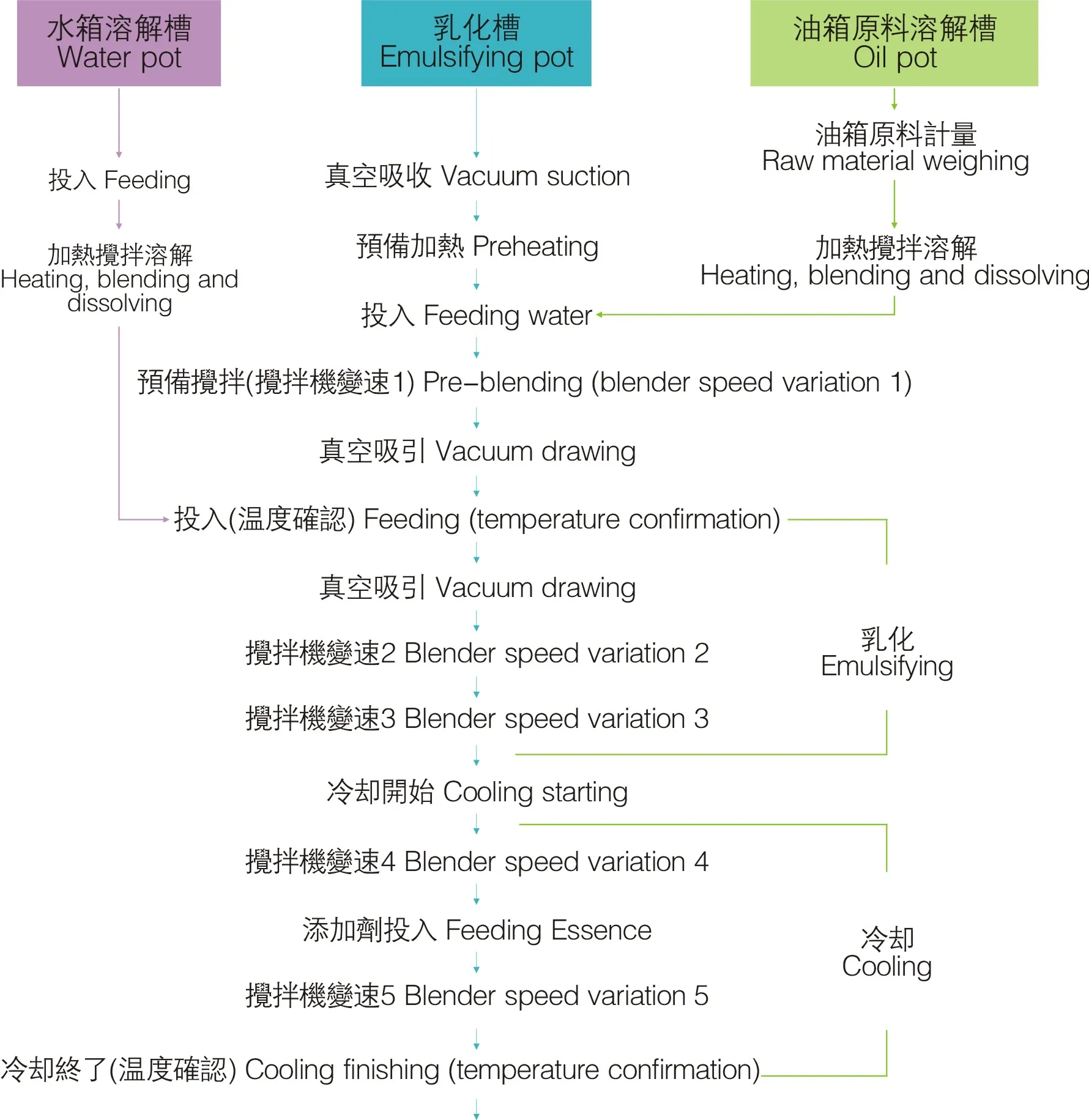

Flow chart of vacuum emulsifying mixer.

Flow chart of vacuum emulsifying mixer.