|

Have any Questions? +86 20 8608 6778 |

XY-B Samll Scale Vacuum Homogenizing Mixer

Feature

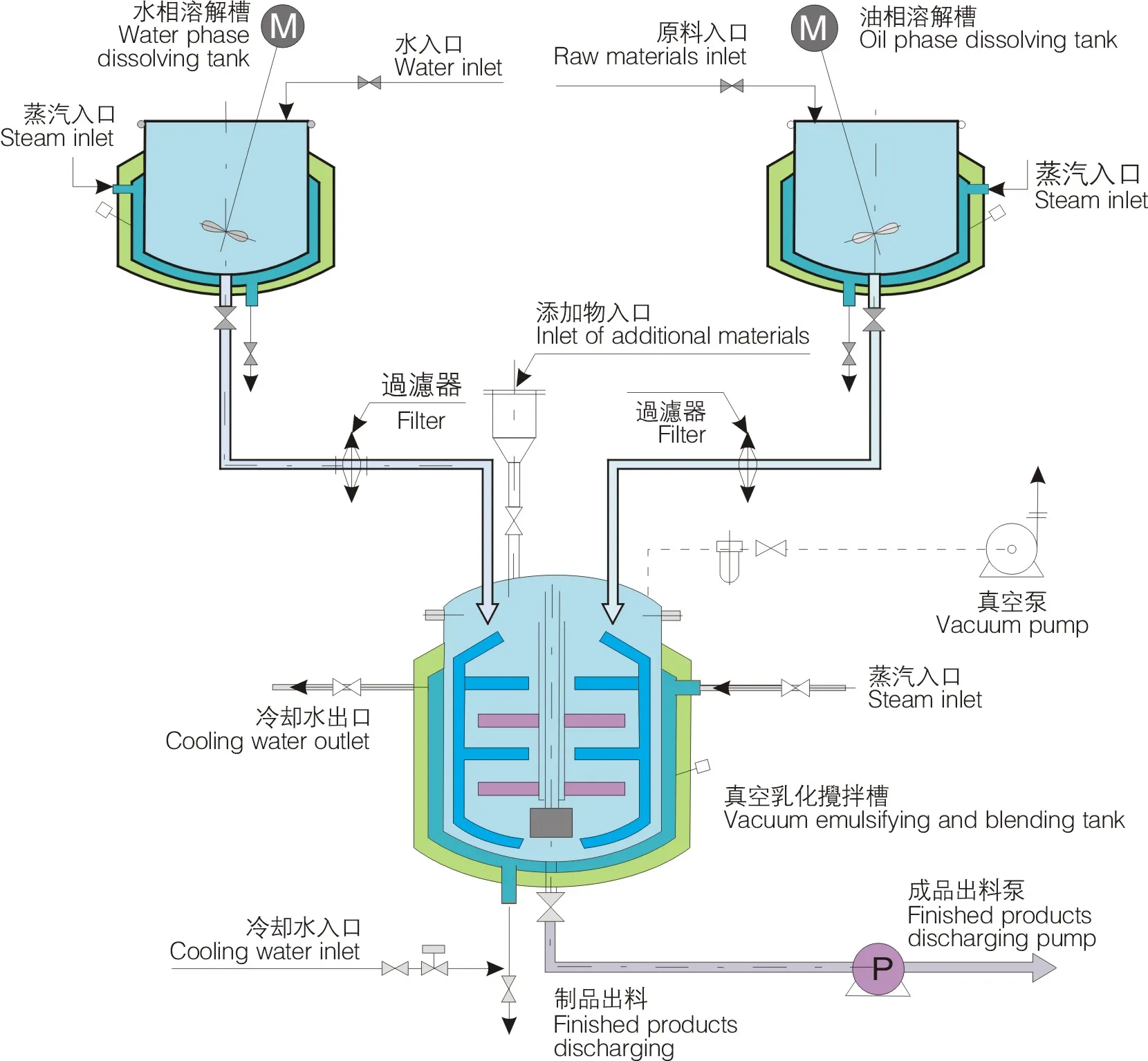

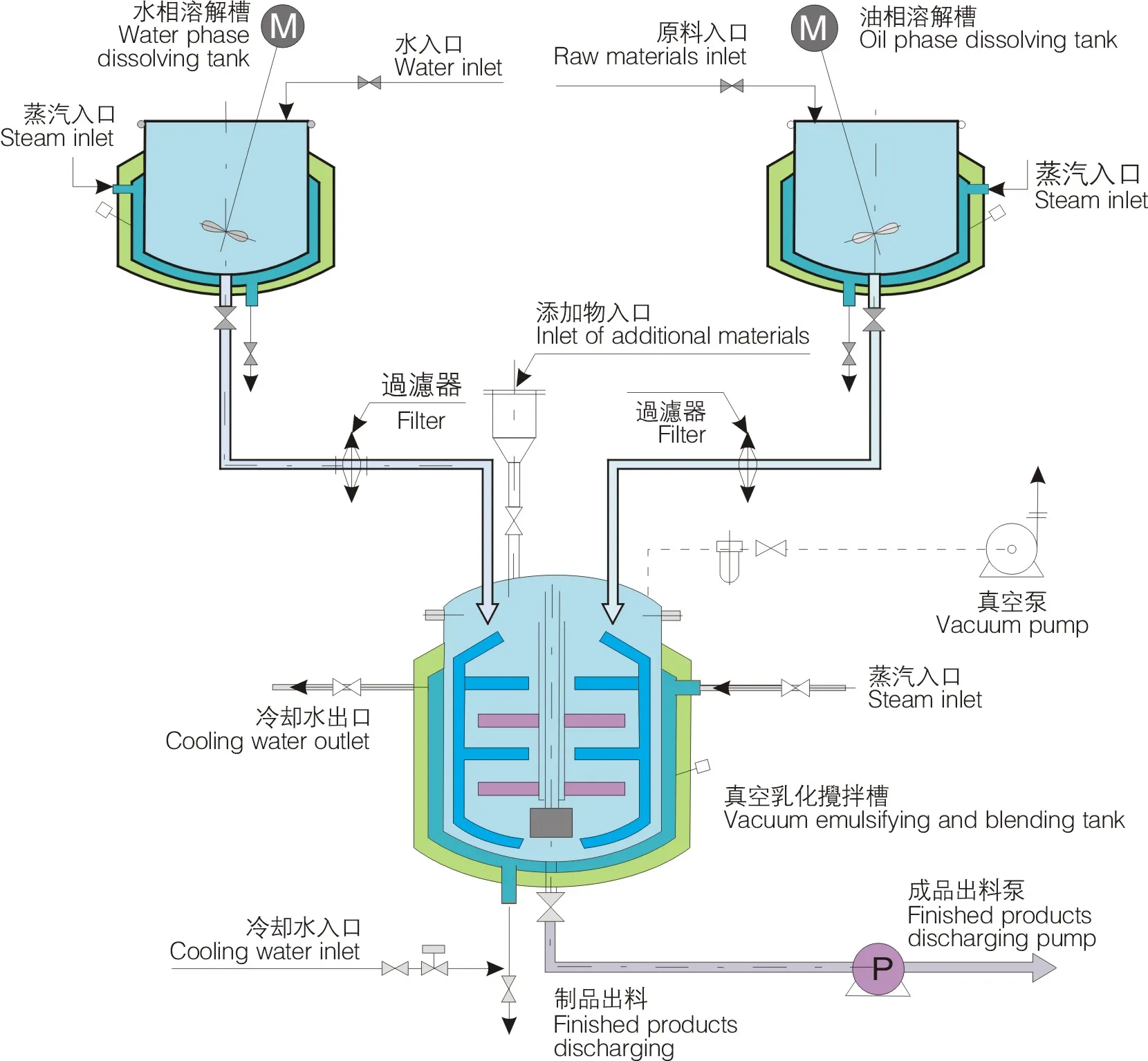

XY-B vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. products through introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump, hydraulic system, dumping system, electric control system and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc.

Feature

XY-B vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. products through introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump, hydraulic system, dumping system, electric control system and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc.

|

|

Advantage

The machine has double blender, hydraulic lift cover, high-speed homogenizer (Speed is 0-3000r/min, frequency speed regulation) and low-speed scraper blender (Speed is 0-63r/min, frequency speed regulation). Fast-cutting vortex emulsification blender is used in the hom ogeneity part, which can scrape in a low speed and automatically blend and snuggle up to the bottom and wall of boiler. The machine draws powder material by the way of vacuum in order to prevent the powder flying. The whole working procedure is operated in he condition of vacuum in order to prevent the material coming int being bubble after high-speed blending and reach the request of sanitation and asepsis. CIP cleaning system is equipped in this system. The contact part of vessel and material is made from SUS316L material. Mirror finish of the inside surface is 300EMSH. In order to ensure the stabilization of the control, the vaccum pump is the products of Chinese famous brand, the button is produced by Schneider or DELIX company, the inverter is the product of Chinese Taiwan Delta. Electric Industries and the electro-con trol part is the product of DELIXI Company. The machine is made completely according to the GMP request, which is the most advanced and most perfect cream production equipment.

Technical parameter:

|

Model |

Volume (L) |

Homogenizer motor |

Stirring motor |

Total power |

Weight(KG) |

|||

|

KW |

RPM |

KW |

RPM |

Electric heating |

Steam heating |

|

||

|

XY-B-5L |

5 |

0.55 |

0-3000 |

0.37 |

0-60 |

6 |

3 |

|

|

XY-B-10 |

10 |

0.75 |

0-3000 |

0.37 |

0-60 |

8 |

6 |

|

|

XY-B-20 |

20 |

0.75 |

0-3000 |

0.55 |

0-60 |

9.5 |

6.5 |

|

|

XY-B-30 |

30 |

1.1 |

0-3000 |

0.75 |

0-60 |

12 |

9 |

|

|

XY-B-50 |

50 |

2.2 |

0-3000 |

0.75 |

0-60 |

18 |

12 |

|

|

|

Advantage

The machine has double blender, hydraulic lift cover, high-speed homogenizer (Speed is 0-3000r/min, frequency speed regulation) and low-speed scraper blender (Speed is 0-63r/min, frequency speed regulation). Fast-cutting vortex emulsification blender is used in the hom ogeneity part, which can scrape in a low speed and automatically blend and snuggle up to the bottom and wall of boiler. The machine draws powder material by the way of vacuum in order to prevent the powder flying. The whole working procedure is operated in he condition of vacuum in order to prevent the material coming int being bubble after high-speed blending and reach the request of sanitation and asepsis. CIP cleaning system is equipped in this system. The contact part of vessel and material is made from SUS316L material. Mirror finish of the inside surface is 300EMSH. In order to ensure the stabilization of the control, the vaccum pump is the products of Chinese famous brand, the button is produced by Schneider or DELIX company, the inverter is the product of Chinese Taiwan Delta. Electric Industries and the electro-con trol part is the product of DELIXI Company. The machine is made completely according to the GMP request, which is the most advanced and most perfect cream production equipment.

Technical parameter:

|

Model |

Volume (L) |

Homogenizer motor |

Stirring motor |

Total power |

Weight(KG) |

|||

|

KW |

RPM |

KW |

RPM |

Electric heating |

Steam heating |

|

||

|

XY-B-5L |

5 |

0.55 |

0-3000 |

0.37 |

0-60 |

6 |

3 |

|

|

XY-B-10 |

10 |

0.75 |

0-3000 |

0.37 |

0-60 |

8 |

6 |

|

|

XY-B-20 |

20 |

0.75 |

0-3000 |

0.55 |

0-60 |

9.5 |

6.5 |

|

|

XY-B-30 |

30 |

1.1 |

0-3000 |

0.75 |

0-60 |

12 |

9 |

|

|

XY-B-50 |

50 |

2.2 |

0-3000 |

0.75 |

0-60 |

18 |

12 |

|

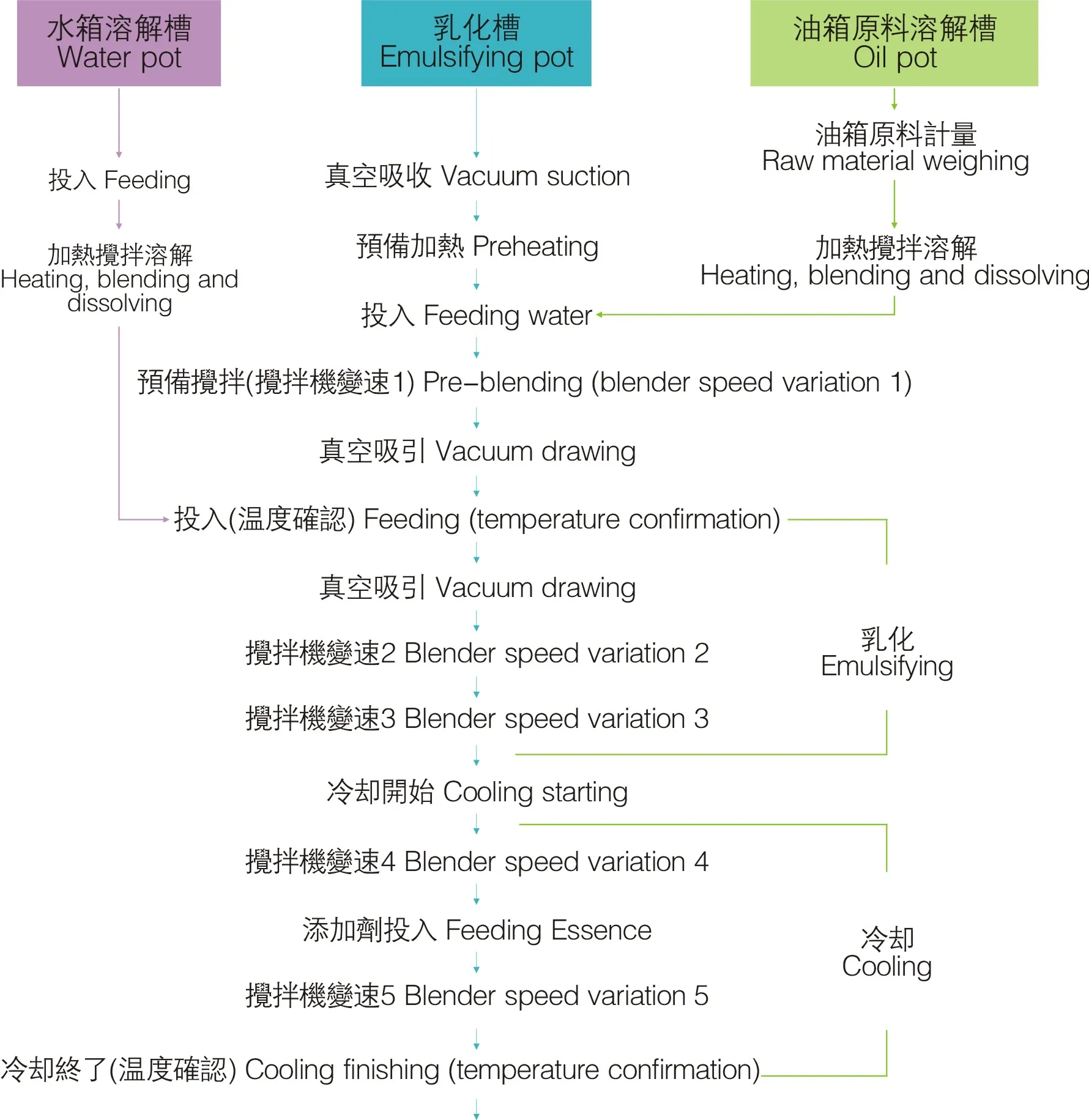

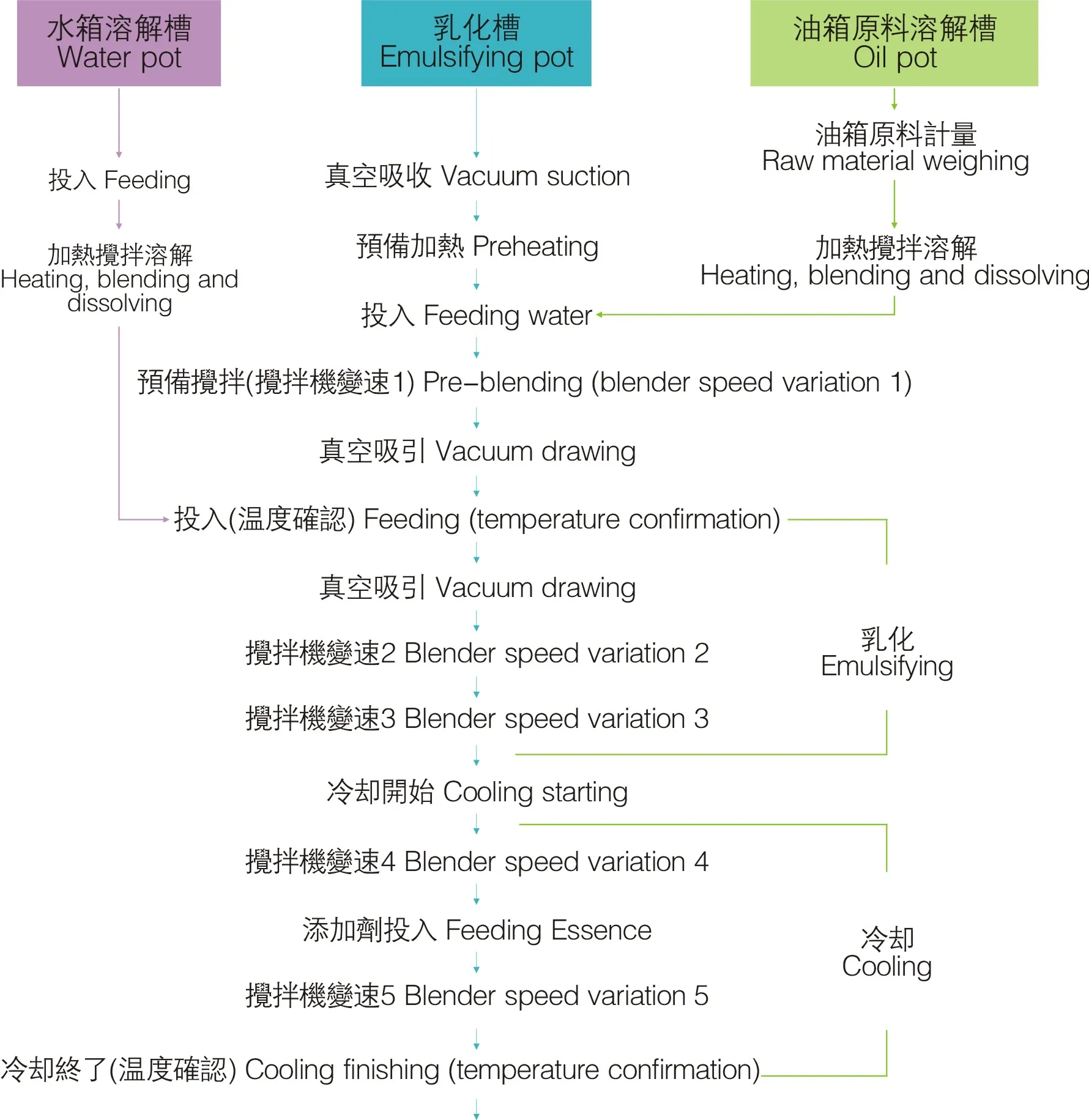

Production Process

Production Process